Cleanroom Installation

1. Definition

By the general definition, a cleanroom is an enclosed space in a manufacturing site or a research center which is specially designed to control the level of air pollution as well as air pressure, temperature, humidity and the contact of staff (natural pollutants from the body parts such as skin, hair, clothes, etc.) to meet the environmental requirements for the manufacture.

Cleanrooms are widely used in the industries such as pharmaceutical production, bio-technology, microelectronics, food processing, etc.

Nowadays, “cleanroom” is a term used to define any area which applies methods for environmental protection but it does not necessarily meet the ISO standards. Therefore, this term can be referred to the process of “environmental monitoring” for the areas in which pollutants, temperature, pressure, humidity and other factors are controlled even when the compliance with cleanroom standards is not required.

2. Materials for the installation of a cleanroom

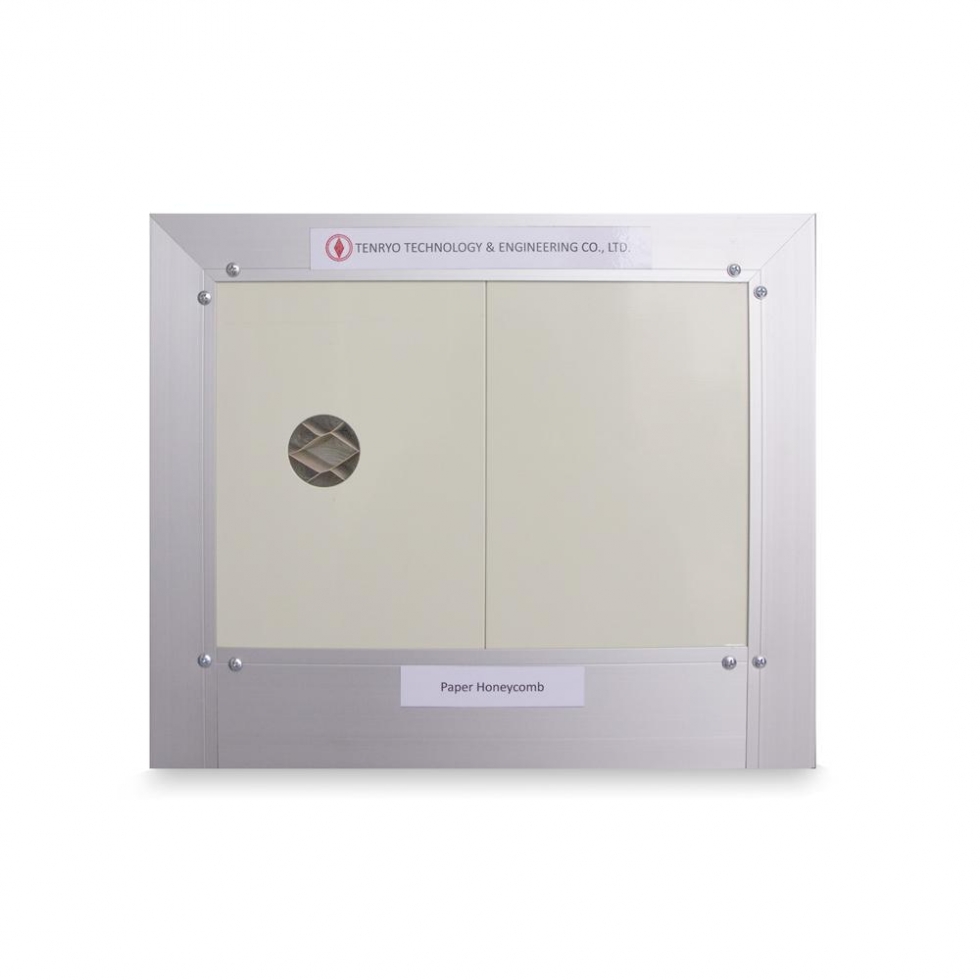

Panels and aluminum alloy spare parts are both provided by TENRYO TECHNOLOGY - TAIWAN.

With the technology from Japan and nearly 30 years of experience in manufacturing the materials for CLEANROOM, TENRO TECHNOLOGY is one of the leading brand names in Taiwan and it has provided its products for both domestic and international projects in different areas including pharmaceutical production, CAS HACCP, GMP food, bio-technology, printed circuit board, photo-electric industry…

One outstanding feature of TENRYO TECHNOLGY is that both panels and spare parts are produced according to the same standard so that the quality of the materials and other technical parameters are guaranteed. This contributes to the solid structure and the perfect assembling of the cleanroom.

3. Cleanroom installation

The installation of cleanrooms has to follow the design approved by the Investor. The quality of a cleanroom has to meet the following requirements

- The quality of materials used for installation: it has to meet the quality standards which a cleanroom requires.

- Installation techniques.

- Quality control during the installation.